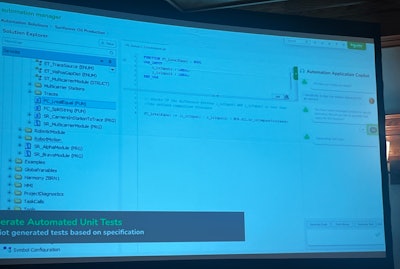

Today anyone can go to ChatGPT, Google’s Gemini, or any other AI chatbot and ask it to write PLC ladder logic. But at PMMI’s annual meeting in late September in Hershey, PA, Schneider Electric and Siemens demonstrated generative AI capability built directly into their software suite for programming those vendors’ PLCs.

Schneider Electric’s John Partin demonstrated how one might go about interacting with the tool to write code for a liquid filling application for olive oil to prevent sloshing during the fill. The programmer can type into a chat box in plain language about encountering sloshing during the fill at a certain speed, and ask it to suggest code that would prevent the undesired behavior. The AI chatbot first asked clarifying questions about the application. After some simple back-and-forth, the AI generated structured text in a pasteboard area on the screen. (It also automatically comments the code for easier understanding.) From that staging area, one can simply copy and paste into the actual code tree on the same screen.

While Partin said that the AI tool is specifically trained on Schneider Electric’s entire library of code, he admitted that right now the tool is limited to the more basic machine handling and isn’t yet ready for advance control functions such as servo motion control or robotic control. But still, it has the potential to save hours of valuable electrical engineering time. To take advantage of generative AI, Schneider Electric set up an AI team last year, and the company’s VP of AI strategy, Juergen Weichenberger, will be giving a demonstration of this functionality at PACK EXPO on Sunday November 3rd. The new functionality is expected to launch after PACK EXPO but a detailed timeframe wasn't released.